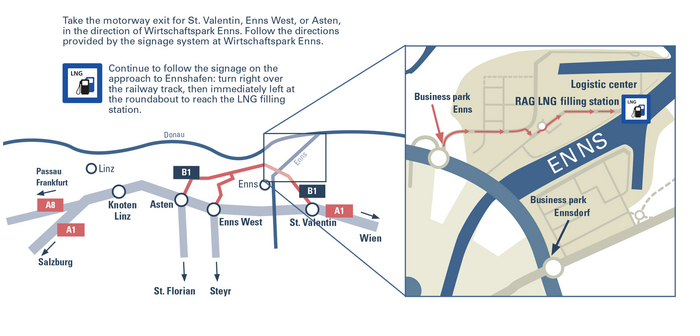

Donaustraße 5, 4470 Enns

The Donaustrasse site in Ennshafen was chosen by RAG for its first LNG filling station due to its ideal location in Upper Austria.

Transport companies that use LNG will be able to refuel vehicles with the fuel of the future without having to make major diversions.

Ennshafen is not only Austria’s newest public port, but also its most modern. The port and neighbouring business parks in Upper Austria and Lower Austria form the largest contiguous industrial zone in the Upper Danube region, with an area of over 350 hectares. As a result of extensive investment in infrastructure and state-of-the-art technology, the port has become a logistics hub for three different modes of transportation, and an important business location for the Enns-Perg-Amstetten area, providing employment for more than 2,000 people.

Visit www.ennshafen.at for more information.